Colors are passion, emotions and personality. At Siegwerk, inks and coatings are our specialty and we use color to bring the packaging and products of our customers to life.

A high-class packaging design combined with a high degree of packaging functionality requires innovative printing inks. We work with you to develop custom ink portfolios to match your requirements. Our experts provide ink formulations, which have exactly the right properties and the functionality you need for your applications.

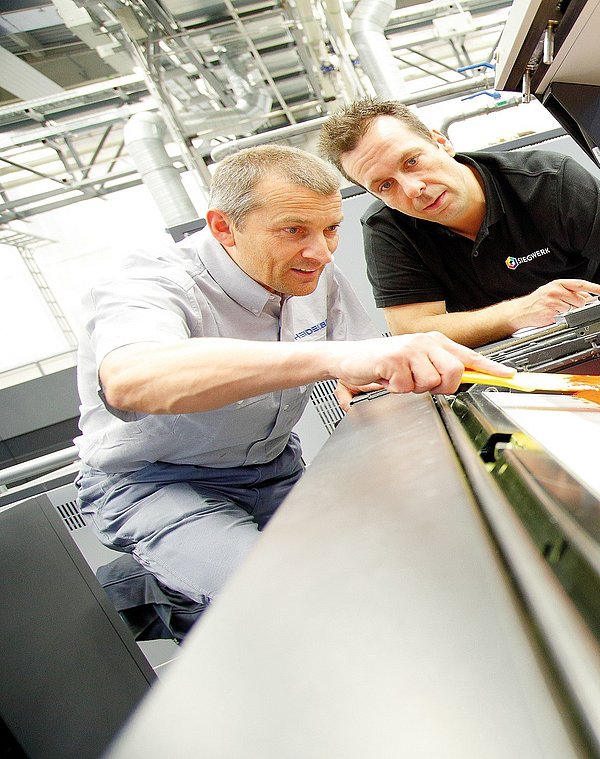

We will assist you as quickly as possible in case of new challenges or if problems occur with your printing presses. Your personal contact will provide you with solutions and enhancements on site. We are not satisfied until everything runs like clockwork. Tests and regular quality checks by our experts ensure your print operations run smoothly.

We also help your employees get up to speed with current quality assurance methods. The result is minimum downtimes and a high degree of profitability.

Food packaging must be absolutely safe. For this reason, we offer you a consultancy service in product safety and regulatory specifications. This knowledge will enable you to behave proactively in the future.

This advice will help you to avoid legal risks in the manufacture of your printed packaging solutions. You will be notified of changes to the regulations in good time, and the detailed information on our printing inks will enable you to evaluate risks and pass this information on to your customers.

This service also includes:

The demands on the packaging industry and package printing are continuously being reviewed and include the desire for outstanding visual appearance while at the same time maintaining excellent package functionality. Better efficiency in the printing and packaging process is also required.

Siegwerk ensures you receive customized ink systems that aligns precisely with your application portfolio. This ensures optimum printing results and reliable processability and therefore saves costs.

We modify the ink recipes if required to increase your process efficiency, or we can optimize the range of printing inks for you to open up further areas of application. If you want to change the characteristics of your packaging, for example to improve the resistance to heat, to produce a high-gloss or matt effect, or to change the sliding characteristics, then we will develop the right solution for you. The same applies to new printing materials such as compostable substrates. In doing so, we always keep an eye on the requirements imposed by the market today and tomorrow. What is more, you can always rely on the perfect interaction between printing materials, inks and adhesives.

Uniform, reliable print quality avoids complaints and rejections, and improves competitiveness. Several ink parameters determine the packaging performance. For example, color strength, covering ability and drying speed are important catchwords in printing. In the further processing field, residues on sealing instruments can also lead to loss of quality as too little bonding strength is achieved. As a further example, constant sliding characteristics and resistance to abrasion are important factors in the packaging process.

We develop test methods for controlling the quality in your print shop during production and – if required – provide assistance in selecting and setting up your own analysis and test instruments. Training of your staff in the new quality assurance methods is undertaken by our experts. As a result, you benefit from a sustained quality improvement for your packaging solution. Fewer faults in production lead to fewer complaints, and strengthen your competitiveness. In short, we ensure stable printing results and safeguard your profit.

New or improved packaging characteristics assist sales and create a competitive advantage. On the one hand, this concerns the packaging design, but, on the other, also improved technical characteristics such as sealing, ability to slide, composition and mechanical or chemical resistance. A good covering capability of the printing ink and gloss or other effects are also part of the equation.

We analyze your applications taking into account packaging design, production equipment and current ink technology to make your packaging innovations reality. Our work also includes searching for alternative solutions with new packaging designs and the best material combinations. Weighing up the various solutions is also part of the service. We assist you with the whole process – from the provision of specialist knowledge to implementation.

We also collaborate with the printing plate, print substrate and adhesive suppliers. In addition, you receive reliable cost-performance overviews and benefit overall from a short and efficient qualification process at optimum cost.

An optimally balanced range of inks offers you many advantages. These include:

This reduction in complexity leads to an ideal balance between packaging effectiveness and functionality.

What is more, your staff do not have to worry so much about stock levels and can concentrate on important tasks.

To simplify your ink range, we first reconcile it with your applications. From this, we then develop customized and lean printing ink concepts.

The ink performance for your specific applications will of course be fully retained. This service also includes evaluating the required functionality and alternative packaging structures.

Faults on printing machines cost money. This knowledge is nothing new, and we have therefore long been a reliable and competent partner when it comes to speedily resolving difficulties in printing or further processing. If required, we also involve our global network of application technology and analytical experts to assist in rapid diagnosis and fault rectification. You can therefore rely on the latest know-how and a wealth of experience. At the same time, we often do more than just resolving the immediate problem. We also show you ways of avoiding difficulties with a view to the future. In this way, quality problems, material rejects, bottlenecks and customer complaints can be significantly reduced.

Service is only as good as its accessibility. Our staff are therefore available at short notice – whether by telephone, e-mail or by an engineer visiting your machine. And it goes without saying that you will have your own personal point of contact.

For your convenience, please also take a look at our:

Packaging printing is often a fast-moving market which expects much flexibility from all those involved. New packaging structures and quality and efficiency expectations require new solutions. For this reason, printing techniques that require the upgrading of flexographic to HD flexographic printing or an increase in printing speed are being developed in the packaging industry throughout the world.

Extended introduction times and, also, more frequent machine shutdowns are often associated with these technical changes. These cost money and play on the nerves. This is why we coach your staff in the use of printing inks directly on the machine. In doing so, we provide them with the necessary skills when introducing new ink and printing technology into production. This enables faults to be identified immediately, and technical and operative solutions to be quickly implemented. To this end, we provide advice on more than just the actual printing ink, for example when the optimum printing plate parameters have to be determined. It goes without saying that our staff are fully up-to-date in their knowledge and have a wealth of experience to build on.