Colors are passion, emotions and personality. At Siegwerk, inks and coatings are our specialty and we use color to bring the packaging and products of our customers to life.

Elevate your packaging game with our high quality innovative solutions tailored for your brand.

Siegwerk provides a comprehensive range of ink and coatings specifically tailored for shrink sleeves, delivering optimal flexibility, durability, and resistance to scuffs, scratches, and blocking. Our solutions excel in terms of slip properties, color strength, anti-wet t-shirt properties, and print quality, all while enabling faster press speeds, minimal waste, and enhanced productivity at reduced production costs. Siegwerk offers cutting-edge ink and coating technologies compatible with a wide array of printing methods, ensuring versatility and efficiency across various print technologies, such as:

Siegwerk supports our customers with high levels of expertise in this application as well as a strong and reliable supply chain and development team to support the ever changing market needs.

Aquantum WB flexo film ink is recommended for use on shrink films and will provide excellent results. These inks are compliant with regulations in the nutrition, pharmaceutical, and hygiene (NPH) applications.

Siegwerk’s solvent ink systems can be used for gravure applications and for flexo applications. These inks allows for fast drying times and high-speed printing, making them ideal for high-volume production environments. These inks are compliant with regulations in the nutrition, pharmaceutical, and hygiene (NPH) applications.

Siegwerk’s SICURA ORBIS LEDtec is a UV/LED system offering excellent adhesion and print performance with all shrink films.

Siegwerk’s Nutriflex ORBIS Dual Cure technology offers very low odor and low migration properties, making it compliant with food safety regulations and NPH (Nutrition, Pharma, and Hygiene) applications.

Siegwerk offers various embellish coatings often applied via rotary screen and cured with either UV or LED lamps. Some of these coatings include tactile effect, sand/grit feel, etc.

SICURA Plast UV/LED offset technology is a great solution for shrink sleeve applications when rotary offset printing is used.

Offerings include glossy, matte, and pearlescent finishes, as well as tactile and sand/grit coatings that provide a unique aesthetic and sensory feel. These coatings have excellent adhesion properties on a wide range of shrink sleeve materials, ensuring that brand messaging, logos, and high-color graphics are protected from scratching and abrasion with rub-resistant properties.

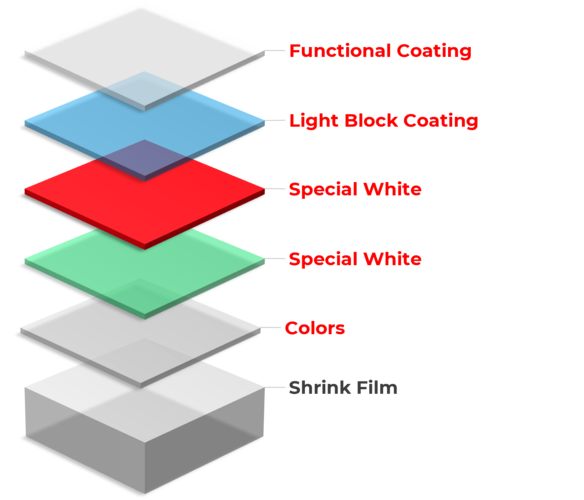

Experience the perfect combination of aesthetics and sustainability with the high opacity white sleeve from Siegwerk. This innovative solution is designed to fit transparent bottles flawlessly, giving you the illusion of a white bottle without the negative impact of non-recyclable materials. By overcoming the challenge of white PET scarcity in certain regions, we offer a practical and modular answer to your packaging needs.

With our high opacity white sleeve, you can effortlessly achieve the appearance of a white bottle on transparent PET packaging. The best part is that the sleeve can be conveniently removed when necessary, allowing for easy recycling of high-quality transparent PET. Plus, we’ve gone a step further by incorporating light-blocking technology into our sleeve, providing enhanced protection for light-sensitive products against harmful UV and visible light. Embrace the best of both worlds with our versatile high opacity white sleeve solution!

Siegwerk has just introduced a revolutionary solution that is a game-changer in packaging. This solution offers numerous benefits, including streamlining processes and reducing costs by eliminating the need for multilayer or colored containers, as well as being carbon black-free. It also caters to the need for sustainable packaging with clear recyclable PET films. And if that’s not enough, the ink/coating is printable, tunable, and ideal for a vast range of light-sensitive applications!

Siegwerk’s ink and coating solutions support Circular Economy with a range of products that meet APR requirements, allowing for the recycling of cPET shrink sleeve and floatable polyolefin shrink sleeve materials.

Siegwerk’s APR recognized de-inking solutions are designed to be washable, with a focus on environmentally friendly and sustainable practices. The Deinking technology ensures fast and reliable wash-off results, without any bleeding of ink ingredients into the washing solution, thus ensuring high quality recycled PET (rPET).

Siegwerk also offers ink-retentive/floatable technology with a range of products that provide excellent shrink performance while meeting APR requirements. These solutions ensure that there is no bleeding of ink ingredients into washing solutions, thus ensuring high quality recycled PET (rPET).

Siegwerk’s shrink sleeve inks and coatings are specially engineered for excellence, offering vibrant, long-lasting colors to ensure that your brand stands out on the shelf. Our formulations prioritize excellent shrinking properties, high flexibility, and resistance to cracking even in folded areas. Additionally, our inks feature high opacity whites that serve as a bright canvas for showcasing messaging and graphics.

At Siegwerk, we are dedicated to ensuring that our shrink sleeve inks perform optimally on press and deliver stunning results on the finished product. Whether you require stronger adhesion, chemical or heat resistance, coefficient of friction (CoF) control, or compliance with regulatory requirements, Siegwerk has the solutions to meet all your shrink sleeve ink and coating needs. Trust in Siegwerk’s expertise to elevate your packaging and enhance the visual impact of your brand.